It’s not just in the movies—robots are now a reality. Until recently, construction was one of the least digitized and automated industries in the world—but times may be changing.

Robots, drones, autonomous vehicles, and 3D printing are some of the new technologies being lauded in the media. While exciting, many of these inventions are not practical for today’s application. Recently, I found a new construction robot from Dusty Robotics that has a promising (and very practical!) future.

Picture by Dr. Tessa Lau from Dusty Robotics

Picture by Dr. Tessa Lau from Dusty Robotics

What is Dusty Robotics?

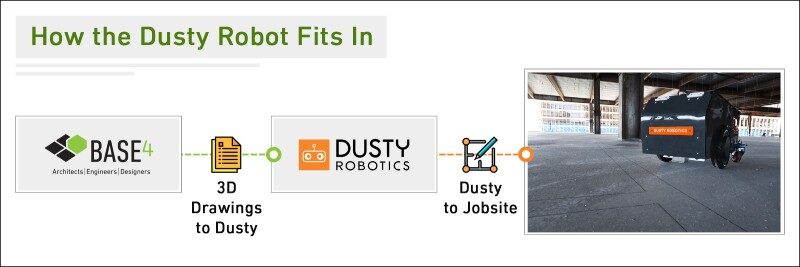

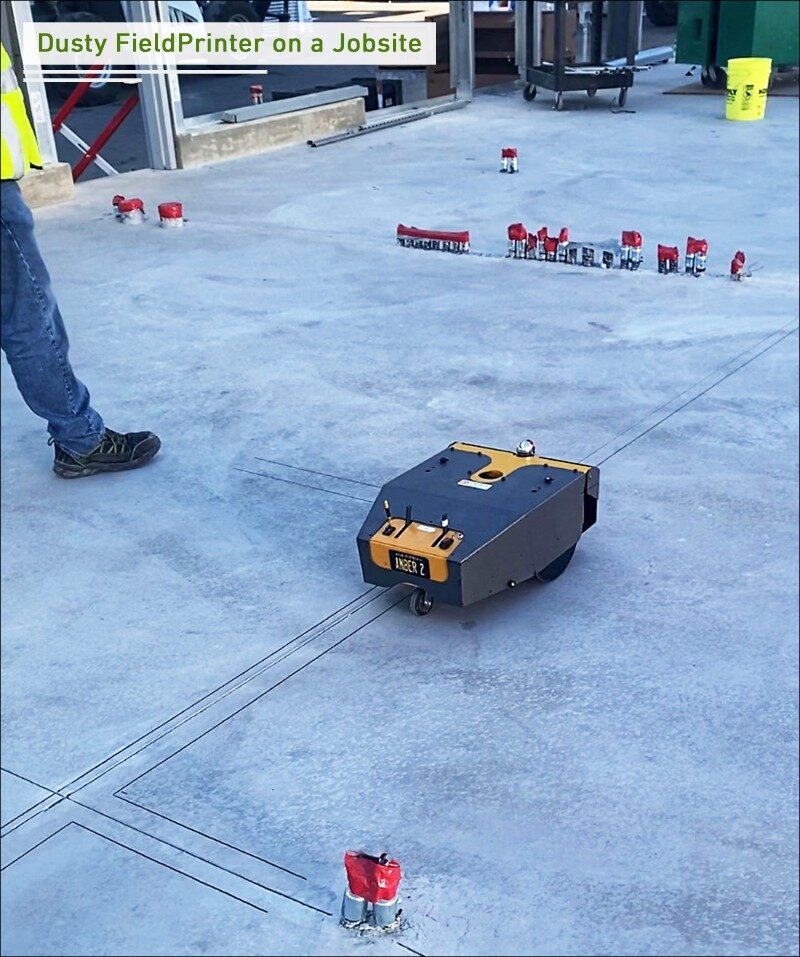

Dusty Robotics designed the first robot to transfer design drawings accurately and quickly to the construction site. You can think of Dusty as a field printer for your construction site. Dusty prints lines, text, points, and curves on flat surfaces such as concrete and mass timber and provides field reports to the construction teams, leading to:

- Faster and higher-quality work

- Instant reporting of work as it is completed

- Real-time monitoring of conditions in the field

This video shows Dusty in action on a job site.

Video by Chris Tobin from Pankow

Why is it important?

Firms like Base4 invest significant hours in BIM (3D) design of new projects. Printed construction plans, however, turn robust 3D data into archaic 2D information. Elements like walls are then laid out manually by pulling tapes and paint lines, which often leads to errors.

This is where Dusty Robotics comes in: Robotic layout eliminates the manual steps and results in faster and much more accurate layouts. Dusty shows the construction team where to build walls and other fixtures.

Chris Tobin, Assistant Project Manager at Pankow, explained that projects using progressive design-build like Dusty could accomplish layout for all trades in one day—with fewer coordination mistakes and higher efficiency.

![]()

The ability to transfer information from a BIM model into the field with 1/8” accuracy heralds an era of greater connectivity and continuity between the design and construction of projects.

![]()

Picture by Chris Tobin from Pankow

Picture by Chris Tobin from Pankow

Dusty Robotics just started rolling out FieldPrinter service earlier this year, starting with job sites in the San Francisco Bay area.

Dr. Tessa Lau, founder, and CEO of Dusty Robotics, is an experienced businessperson with expertise in Artificial Intelligence, machine learning, and robotics. We asked what are her thoughts on using robots in the construction industry:

![]()

I see enormous potential for robotics to turn construction into a data-driven manufacturing operation. As more and more projects adopt digital modeling tools, these models are going to become the instruction manual for robots to use to turn designs into reality.

What we’re building at Dusty is just the first step of automating this BIM to field workflow and setting the stage for further automation of construction work, making jobsites safer and more efficient.

![]()

Keep an eye out for Dusty Robotics and reach out for news on all the latest technologies to aid you in your next project. BASE4 is dedicated to using cutting-edge design/build technology to save you time and money.

In keeping with our commitment to construction innovation, we started Stonepile Construction College, where students learn about Dusty Robotics and other practical construction innovations. Feel free to contact me if you have any questions. Enrolling now for our January 2021 start date!

Interested in innovating?

Thank you,

Blair Hildahl

BASE4 Principal

608.304.5228

BlairH@base-4.com

![]()