Why?

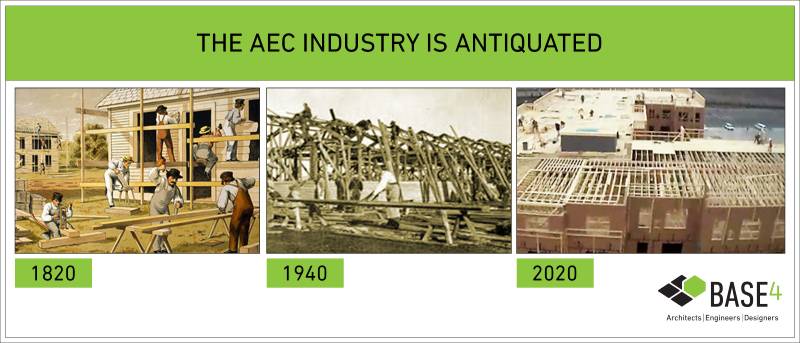

The AEC industry is broken. We are still building projects the same way we did years ago.

There is!

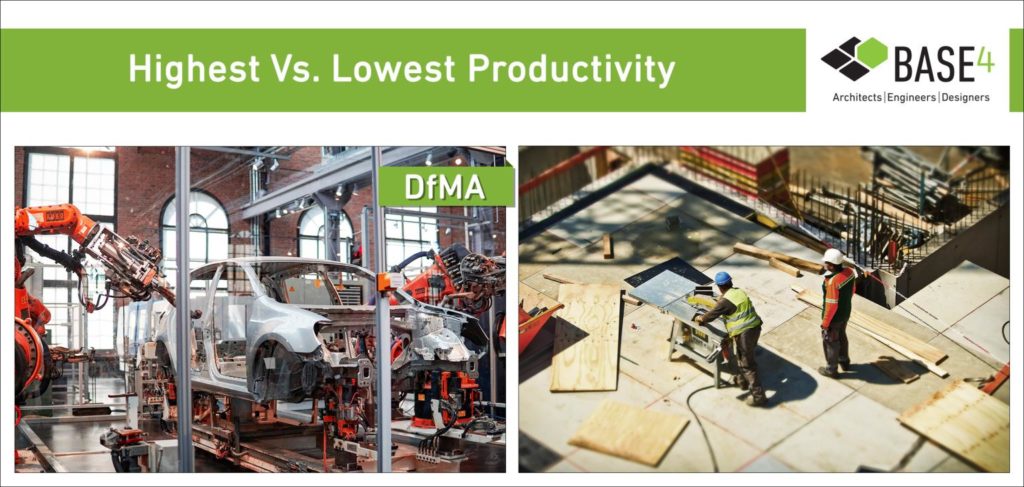

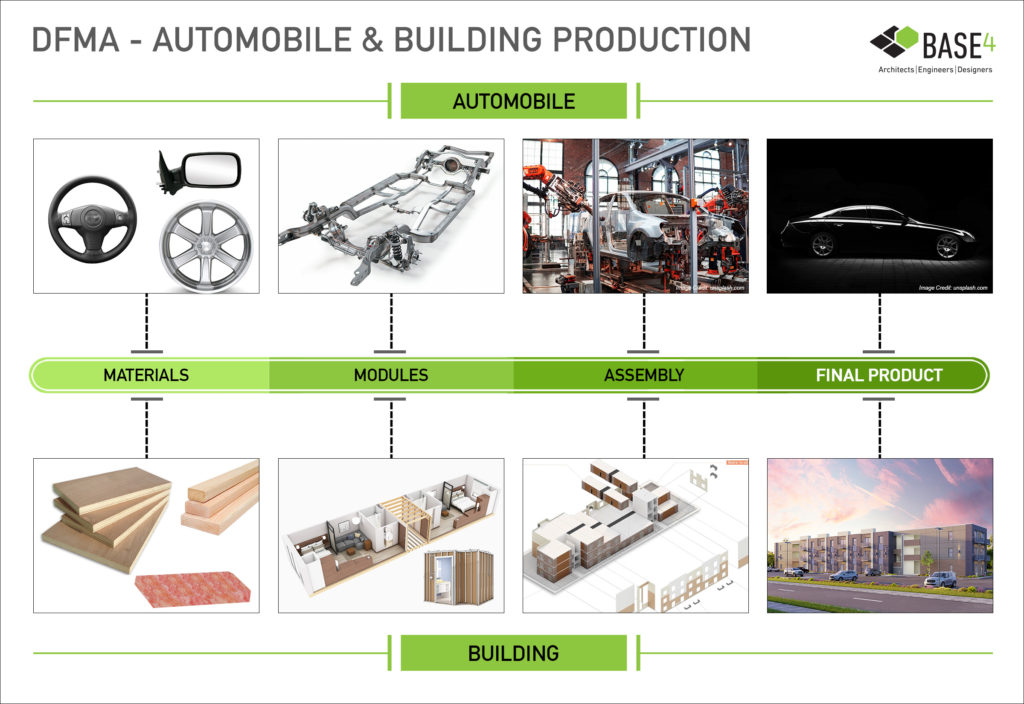

Every other intricate product--from cars to planes to ships--is built using Industrialized Construction.

Projects are delivered faster, cheaper, and with better quality.

Industrialized Construction (IC) combines the best of prefabrication, automation, AI, factory robotics, and DfMA.

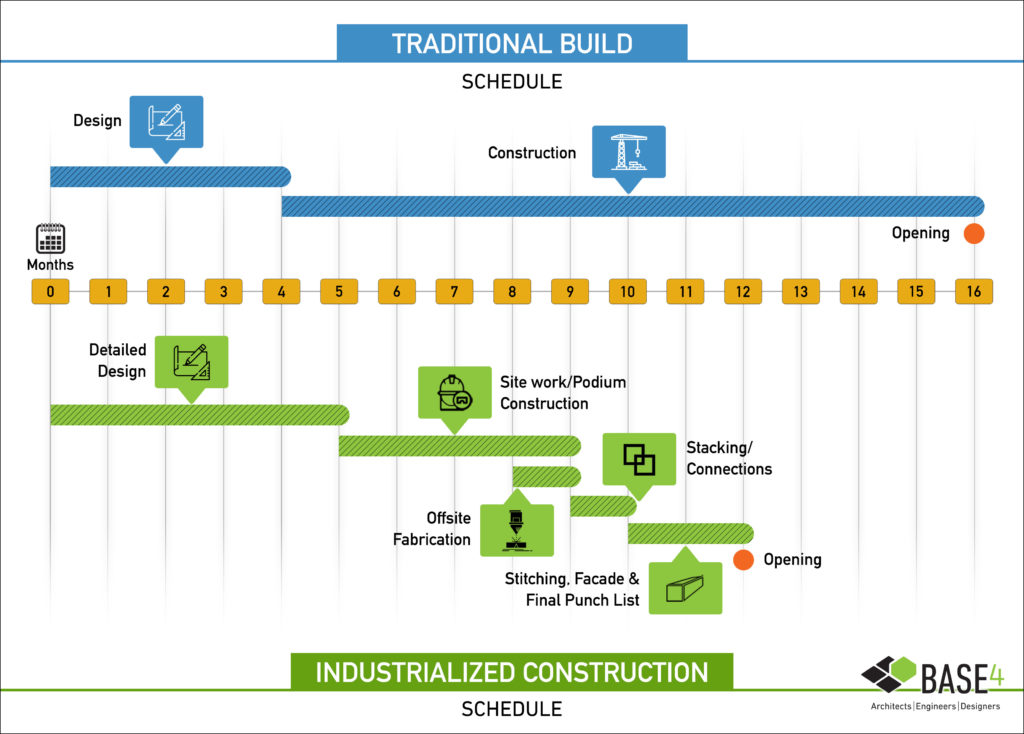

Modern techniques put construction on the assembly line in a manufacturing plant, away from the jobsite. McKinsey & Company reported 20-50% acceleration in timelines for modular construction projects.

So how can you use IC initiatives on your next project? Well here are a few places to start:

Volumetric modular is a process of stacking and connecting factory-finished module units to form a substantially complete building. These can be built with wood, light gage, or structural steel.

Bathroom pods bring all the components of a bathroom—complete with finishes and MEP connections—in one finished and coordinated package.

For more information on bathroom pods click here.

Flat-panel units are built in a factory and later transported to the site to be assembled into a three-dimensional structure or to fit within an existing structure. The panels can be made of steel, timber construction materials, concrete, or masonry. Systems can include walls, floors, and roof panels to create the complete structural shell.

There are three main types of panelization:1

- Wooden Frame Panels: Timber-frame panels may be specified as open or closed panels. These panels are based on a structural framing system, which can have factory-fitted windows, doors, MEP services, internal wall finishes, and external cladding.

- Cold-Formed Steel Panels (CFS): Similar to the Wooden Frame Panels – with CFS, the wooden framing members are replaced with thin steel sections. The steel sections used here are called cold-formed sections, meaning the sections are formed or given shape at room temperature.

- Structural Insulated Panels (SIPS): A sandwich-structured composite, consisting of an insulating layer of rigid core sandwiched between two layers of structural board. The board can be sheet metal, plywood, cement, and polyurethane foam. SIPs are manufactured under factory-controlled conditions and can be custom-designed for any project. They do not rely on internal studs for their structural performance.

Now you might be wondering if other components—like floors, roofs, and even elevator—can be fabricated in the same method as the Bathroom Pods and the answer is YES.

Larger components can be incorporated into either conventionally built or Modern Methods of Construction (MMC) dwellings.

Here are a few of the most common components that can be assembled offsite:

- Prefabricated foundations

- Floor/roof cassettes

- Prefabricated dormers

- Multi-trade racks

- Modular elevators

- Prepackaged Kits

- Stairs

At a modular factory assembly line

We at BASE4 have mastered the art and science of industrialized architecture–or DfMA. But more importantly, we realize the need for education. Our goal is to transform the building industry through training, technology, and innovation, so that we can collectively reach our maximum potential.

If you’re looking for ways to rethink construction, I invite you to reach out with your ideas and questions.