Here’s how modular construction automatically fixes the noise problem

Hearing the neighbors’ conversation in the next room is only good for movie plots! In reality, noise complaints hurt business. This much-discussed topic deserves more attention—and modular gives it a whole new outlook.

So today, we’ll discuss how modular construction stacks up against traditional wall assemblies when it comes to sound insulation. Read on!

What’s the Problem?

Noise is among the top complaints of your occupants. Whether it’s a hotel guestroom or an apartment building, noise transmission is bad news for privacy and quality sleep. There are two major sources of noise transmission:1

- Noise from the outside: Buildings near highways, amid dense urban neighborhoods, and in the airport area, are prone to unavoidable noises and the vibratory airborne waves of heavy-duty vehicles.

- Noise from adjacent units: Due to poor sound insulation, noise from adjacent units of homes and hotels pollute the rooms next door.

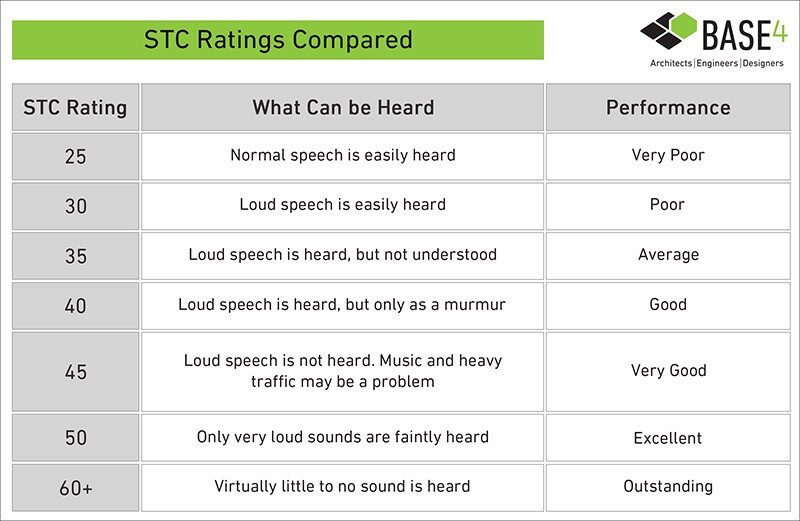

A Glance at STC

Noise transmits through walls, windows, doors, floors, and ceilings. Sound transmission class indicates a material’s capacity to block sound from passing through different wall assemblies.

A higher STC rating means better soundproofing. The table below puts these numbers into perspective.

How the ratings work: Suppose the sound on one side of a wall is 90 decibels, which drops to 60 decibels on the other side. This means the wall can block 30 decibels—earning it an STC rating of 30.

Modular Construction Provides an Automatic Fix

Modular factories prepare each volumetric box as a separate unit. This means that in the final product—i.e. the modular building—each stacked up module has its own walls, floor, and ceiling. (I answer frequent questions about modular here.)

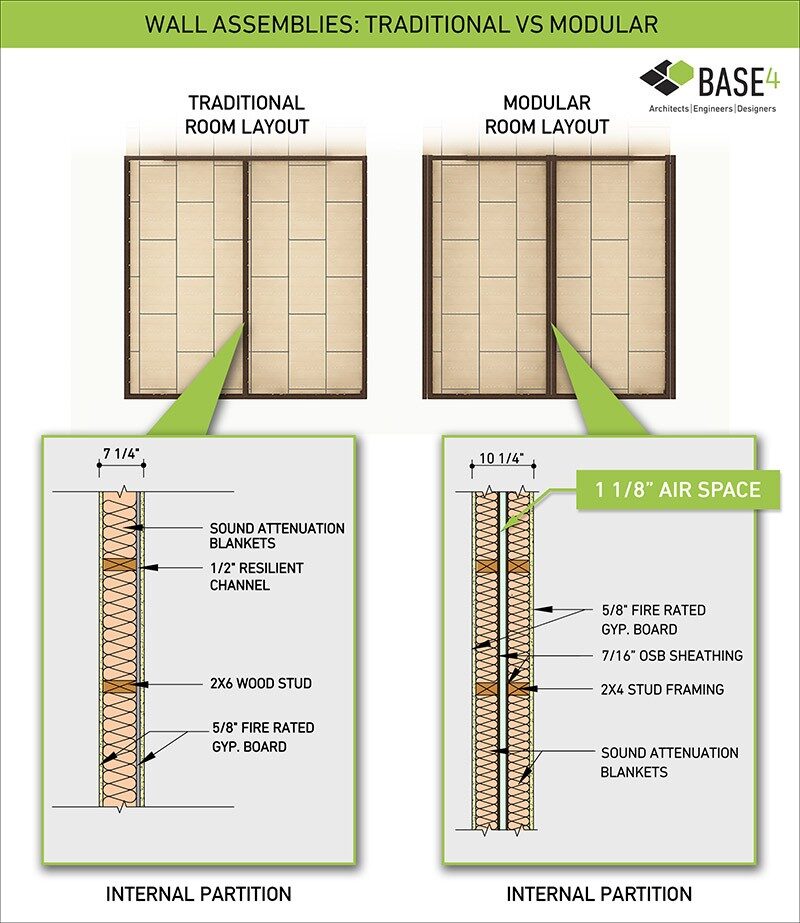

This means that no two adjacent modules share a common surface—resulting in an average of 1” air gap between each set of two modules. Turns out, these air gaps improve sound insulation.

- Sound transfers mainly by vibration. Air gaps between walls disconnect the path for the vibration to travel.

- One of the most effective ways of providing a high STC rating in stick-built construction is to disrupt the path of sound transmission with separate plates and framing in the wall.

- In modular construction, the walls between modular units are automatically separated and insulated, providing a superior STC rating without the use of resilient channel (RC) or proprietary assemblies.

- The combination of the increased depth of the floor-ceiling assembly and the independent structure provide high STC ratings for both ambient and impact sound ratings.

- This method of using an increased air gap applies to both, the walls and ceiling/floor assemblies, thus giving each module superior STC ratings on all sides.

- Due to this premium sound rating, an owner can choose a more durable flooring without having to upgrade the assembly with expensive and proprietary sound clips.

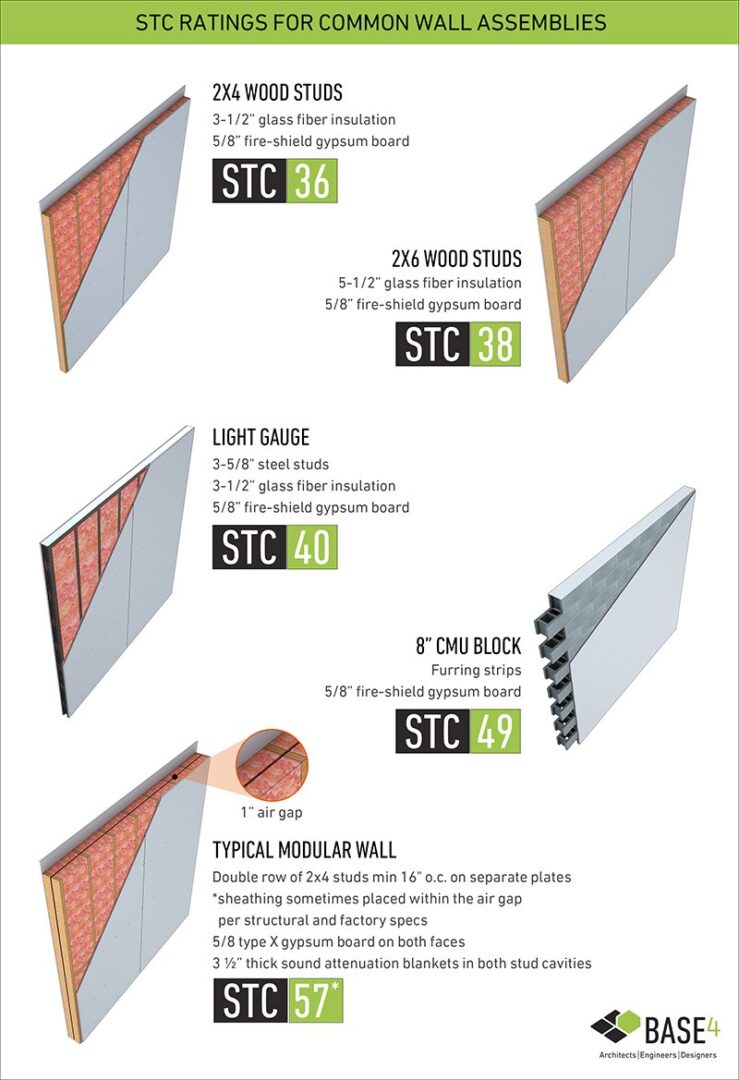

Here’s how common wall assemblies measure up against one another for sound absorption. Note that STC ratings are subjective and any windows, doors, and other “holes” in the wall will affect overall STC ratings.

Since modular units are produced in a quality-controlled factory environment with precision cuts and quality materials, the chances of getting superior STC ratings are much higher than in traditional builds. (Find out the right time to go modular.)

The Whole Story

While a good STC rating is the first step toward insulating noise, two other indicators factor in: the Noise Reduction Coefficient (NRC) and Impact Isolation Class (IIC).

The NRC indicates low-frequency airborne sound absorption while IIC deals with vibratory sound coming from the floor (e.g., footsteps).2 Keep watching this space for an upcoming newsletter on the topic.

Meanwhile, let’s chat if you want to understand more about the complexities of noise insulation for your upcoming project. You can also fill out this form. Until next time!

![]()

Thank you,

Blair Hildahl

BASE4 Principal

608.304.5228

BlairH@base-4.com

![]()